Recommended Printers, Ink Sets, Layering Instructions

IMPORTANT! Quality and Durability of the Transfer Decal produced is determined by the following factors. First, the most important factor is the Ink Set that is installed in your printer. If the Ink Set installed is “too hard”, the decal may crack or fracture when being applied to surfaces with complex curvatures or sharp corners. Conversely, if the Ink Set installed is “too flexible/soft”, the decal will tend to Bubble or have an Orange Peel effect. This phenomenon will happen during application, or after it has been applied. The second important factor is how you choose your Ink Layering Structure. Last, but not least, is the performance of the printer and profiling software being used.

There's a plethora of printers and ink set options in the market, and we're continually updating information on which printers and ink sets will produce optimized decal performance.

PRINTERS and INK SETS

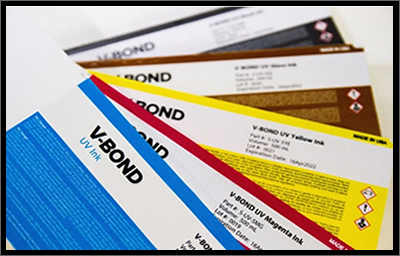

Roland VersaUV LEF2-300. Or any other Roland UV Flatbed Printer using V-Bond Inks works extremely well with Magic Film. Multiple print facilities have reported that, when producing UV DTF Transfer Decals with V-Bond inks, the finished result is a Transfer Decal exhibiting superior durability. Note: We have determined that using any Roland UV Ink other than V-Bond will produce unacceptable results. Finished decals using an alternative ink such as EUV, EUV4 or others will produce decals that exhibit Orange Peel/Bubbling effects that will appear before or after the decal has been applied.

Roland VersaUV LEF2-300. Or any other Roland UV Flatbed Printer using V-Bond Inks works extremely well with Magic Film. Multiple print facilities have reported that, when producing UV DTF Transfer Decals with V-Bond inks, the finished result is a Transfer Decal exhibiting superior durability. Note: We have determined that using any Roland UV Ink other than V-Bond will produce unacceptable results. Finished decals using an alternative ink such as EUV, EUV4 or others will produce decals that exhibit Orange Peel/Bubbling effects that will appear before or after the decal has been applied.

View More Info On Roland V-Bond

LogoJet UVX40r. Or any other LogoJet UV Flatbed Printer using Hard Inks. We've had great success with this printer when using the Hard Ink Set on Magic Film. There have been numerous reports confirming that this Ink Set also produces a Transfer Decal exhibiting superior performance. Many samples have been produced and performance testing done, yielding excellent results.

Mimaki UJF-6042 MkIIe. Or any other Mimaki UV Flatbed Printer using LUS-150 Inks works extremely well with Magic Film. All print facilities using these inks have reported that, when producing UV DTF Transfer Decals with LUS-150 ink, the finished result is a Transfer Decal exhibiting superior durability. Note: We have determined that using any Mimaki UV Ink other than LUS-150 will produce unacceptable results. Finished decals using alternative ink such as LUS-120, or LUS-170 which are extremely flexible, will produce decals that exhibit Orange Peel/Bubbling effects that will appear before or after the decal has been applied. Conversely, using LH-100 inks which are considered a Hard Ink will produce a decal that may crack or fracture when applying, due to inflexibility of the ink. In some cases, LH-100 inks may be utilized depending on the intended end use/application. Please call or email for additional information.

Compress UV 1200s. Just added to our list of recommended printers. The addition of this printer is based on information provided by the business owner, who reported that excellent results were achieved. Owner/operator also stated that, printer is using original Compress P70i Hard Inks, and used Ink Layering Structure #1.

*Caution, updated results show that this hard ink set still produces an excellent finished decal. Due to the hard inks charactaristics they ARE NOT dishwasher resistant. We are currently gathering information, regarding Dishwasher Resistance when using Compress Hybrid. We will update test results, as soon as soon as they become available.

Mutouh Xperjet 661 UF. We've ran a limited number of samples using this equipment but have found that the Hard Ink Set seems to work well. We will update which Layering Structure works best, after further testing and additional customer feedback is made available.

LAYERING STRUCTURE OPTIONS

Layering structure #1. which has been modified from Standard Layering Structure Produces the Most Durable Decal providing Superior Performance. Note: this layering structure adds additional height/relief to the image, yielding a slightly embossed effect.

Gloss Clear/(Varnish) x1, White x1, C, M, Y, K, Gloss Clear/(Varnish) x2.

Layering structure #2. Produces a Highly Durable Decal providing Excellent Performance.

Gloss Clear/(Varnish) x1, White x1, C, M, Y, K, Gloss Clear/(Varnish) x 1.

Layering structure #3. (Standard Layering Structure) Produces a Very Durable Decal providing Good All-Around Performance.

Downlaod PDF chart here | White x1, C, M, Y, K, Gloss Clear/(Varnish) x 1.

Layering structure #4. Produces a Very Durable Decal providing a Dense Opaque White Backing with Good All-Around Performance.

White x 2, C, M, Y, K, Gloss Clear/(Varnish) x1.

Layering structure #5. Produces an Exaggerated Embossed Effect with Dense Opaque White Backing. Depending on the Ink Set used, it may cause cracking or fracturing of the decal. This is a very time and ink consuming structure to produce.

Gloss Clear/(Varnish) x 1, White x 2, C, M, Y, K, Gloss Clear/(Varnish) x1.

Layering structure #6. Produces an Extreme Embossed Effect with Dense Opaque White Backing. Depending on the Ink Set used, it may cause cracking or fracturing of the decal. This is the most time and ink consuming structure to produce.

Gloss Clear/(Varnish) x 1, White x 2, C, M, Y, K, Gloss Clear/(Varnish) x2.

Layering structure #7. Produces an Extremly Tough, but Rigid Decal. The following structure utilizes Mimaki LH-100 inks. Performance of this decal is limited to those looking for extreme toughness. Caution: Decal will possibly crack, or fracture due to inflexibility of the ink. Also, LH-100 inks do not offer fade resistance, and are not intended for outdoor use.

Gloss Clear/(Varnish) x1, White x1, C, M, Y, K, Gloss Clear/(Varnish) x1.

NOTE: Any of the above layering structure options can be used. Based on your specific application, and performance requirements, the choice of layering structure is ultimately your decision.